Production process

O.ME.P.S. is one of the most impressive manufacturing companies in Italy.

The manufacturing plant and its staff ensure a production capacity of more than 600 silotrailers per year, and each unit has an average life cycle of 25 years. Such results are based on a production protocol characterized by innovation and reliability.

Here below, step by step, you can see the route leading to the creation of an O.ME.P.S. silo trailer:

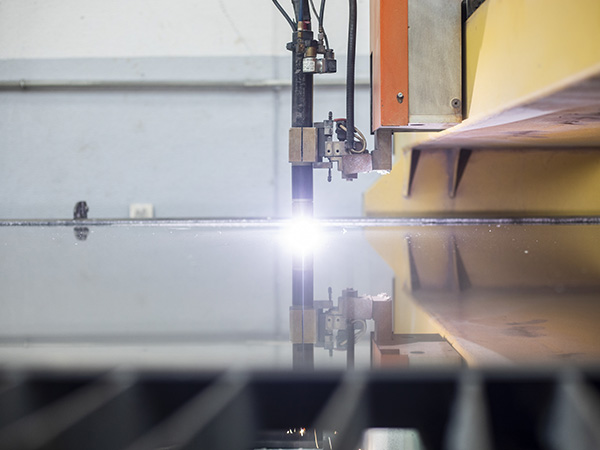

1

Transposition of each single component on the aluminum sheet and cutting via computerized plasma cutting machine.

2

Folding of the pieces to create a kit of parts for fabrication, assembly of the tank shell and frame.

3

MIG and TIG welding with Argon Inert Gas shielding

4

Double layer painting with four stages of initial preparation.

5

Final mounting – all component parts are put together again after painting

6

Alignment of the axles and parameterisation of the braking system.

Each one of these steps involves a series of inspections and checks, since the aim is to produce consistently a tanker that meets all the required operational characteristics, and, above all, is safe and reliable.

The exclusive use of aluminum leads to important advantages

- decreased tare weight

- increased payload

- reduced number of trips

- lower fuel costs

- lower CO2 emissions and lower CO2 help us to play our own part in saving the environment

Five excellent reasons convincing more and more transport operators to choose O.ME.P.S.. But not the only ones.

Aesthetic

Amongst the most appreciated reasons is aesthetics. It’s never just an issue of simple appearance: the level of finish and the customization of all our vehicles are essential components in O.ME.P.S. production process culminating in the delivery of elegant and reliable vehicles that combine good looks with unbeatable value for money.